Consultancy Services

-

Ready-Mixed Concrete

Certification

MS EN 206:2016 & CIS 21:2018 -

Precast Concrete - IBS Element

Certification

BS EN 13225, BS EN 13747, BS EN 14992 & IMPACT -

Precast Concrete

Concrete Piles Certification

MS 1314 Part 1, 2, 3, 4 ,5 -

Contractor Management System(coming soon)

Certification

CQMS ISO 9001:2015 & CIS 29:2021

-

Ready-Mixed Concrete

Certification

MS EN 206:2016, CIS 21:2018 -

Precast Concrete - IBS Element

Certification

BS EN 13225, BS EN 13747, BS EN 14992 & IMPACT -

Precast Concrete

Concrete Piles Certification

MS 1314 Part 1, 2, 3, 4 ,5 -

Contractor Management System(coming soon)

Certification

CQMS ISO 9001:2015 & CIS 29:2021

Get Your Product Certification

Easier, Faster & Hassle-Free Way

Faster

*Subject to the available data/documents provided by client.

Easier

Hassle-Free

Certification Process

01 - Analysis

Identify the gap towards certification for example: have customer register their product to CIDB for certified construction material?

02 - Customised consultation

Each business are unique, therefore we will customise and deliver our consultation programme according to your business requirement (Contech team is present to guide on the forms & paperwork)

03 - Hassle-Free implementation

We assists in developing a straight forward and “easy-to-maintain” quality manual documentation system with minimal workload to handle.

04 - Knowledge Transfer

Provide step-by-step guidance to your personnel, before and after the implementation of PPS / PC certification.

05 - Internal Audit

We will review the compliance of your product with Construction Industry Standards and Fourth Schedule Act 520 CIDB (Amendment 2021)

06 - Certification Support

We have well qualified consultant to provide “A – Z” assistance on preparation and external audit by accredited certification bodies such as Certibuild (M) Sdn Bhd and Construction Research Institute of Malaysia (CREAM).

Ready-Mixed Concrete Certification

MS EN 206:2016 & CIS 21:2018

Under the Forth Schedule Act 520 CIDB (Amendment 2021), one of the provisions in the amendment act in to ensure that construction materials used in Malaysia must comply with certain mandatory standards.

CIDB as the government agencies is then being empowered to monitor and enforce construction materials on the market.

The regulation and guideline for ready-mixed concrete industry is clearly stated under CIDB Construction Industry Standard (CIS) 21:2018 that coherence with Malaysia Standard (MS EN 206:2016)

It is mandatory for Ready-Mixed Concrete player to comply the above regulation prior deliver their products for construction usage. CIDB as the government agencies is then being empowered to monitor and enforce construction materials on the market

- Comply to latest regulation under CIDB Fourth Schedule Act 520 (Amendment 2011)

- Ensure the delivered concrete is complying to certain standard before being used (fit for purpose, value for money, customer satisfaction).

- Ensure construction materials guarantee the safety of the publics & construction workers

- Ensure environment preservation

- Improve the image of the country’s construction Industry

- Ensure construction materials meets the highest regulatory standards before usage at construction site

- Promote standardization in building material among ready-mixed concrete players

- Boost acceptance and confidence of a certified construction material to customer & regulatory body

- Comply to latest standard on local Construction Materials under Fourth Schedule Act 520 (Amendment 2011)

- Facilitate fair and transparent trade in building and construction industry

Ready-Mixed Concrete

Product Certification Framework

What is the application process to obtain CIDB PPS for Ready-Mixed Concrete manufacturer?

Step 1

Engagement with approved / recognized Certification Body (CB) to obtain Product Certificate (PC Cert)

Step 2

Apply for Perakuan Pematuhan Standard (PPS) through CIDB official website

Step 3

Verification completed by CIDB enforcement at batching plant & issuance of CIDB PPS Certificate

Precast Concrete - IBS Element Certification

BS EN 13225, BS EN 13747, BS EN 14992 & IMPACT

Precast Concrete – IBS Precast Element & IMPACT certification involves an application process, assessment procedure, application approval and

certification before being recognized as a manufacturer of IBS components registered with CIDB.

Precast Concrete – IBS Precast Element Certification & IMPACT certification commonly used in the construction sites are:

- BS EN 13225 – 2013 Precast Beam / Column

- BS EN 14843 – 2007 Precast Stairs

- BS EN 14992 – 2007 Precast Concrete – Solid Wall Element

- BS EN 13747 – 2005 Precast Product – Floor Plates for Floor

- Ensuring all construction materials achieve a high level of quality before being used in Construction industry (fit for purpose, value for money, customer satisfaction).

- Ensure construction materials guarantee the safety of the publics & construction workers

- Ensure environment preservation

- Improve the image of the country’s construction Industry

- Avoid poor quality construction materials do not enter the local market – anti dumping

- Identifies high quality and guaranteed IBS Precast products

- Boost high confidence in IBS precast products

- IBS Precast product closely monitored and complied to strict standards

- Increase commercial value of IBS Precast product

Precast Concrete – IBS Precast Element & IMPACT Certification

What is the application process to obtain IBS Precast Element & IMPACT certificate ?

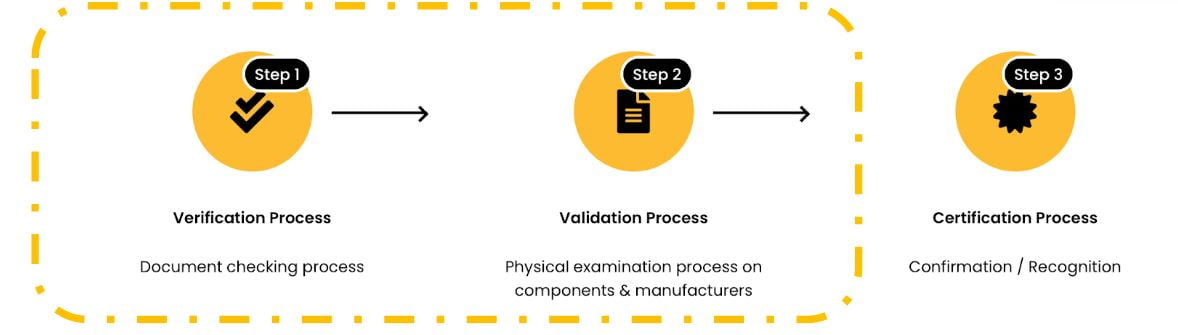

Evaluation Process

01 - Verification Process

We will request from customer side submit all the relevant document for checking for IBS IMPACT application process.

02 - Validation Process

We will schedule a physical examination on IBS components & assists customer to attend factory audit with the Certification Body – CERTIBUILD (M) Sdn Bhd & CREAM.

03 - Certification Process

The certification body will issue the Perakuan Pematuhan Standard (PPS) Certification to the customer.

Precast Concrete – IBS Precast Element & IMPACT Certification

What is the application process to obtain IBS Precast Element & IMPACT certificate ?

Step 1

Engagement with approved / recognized Certification Body (CB) to obtain Product Certificate (PC Cert)

Step 2

Step 3

Verification completed by CIDB enforcement at precast yard & issuance of CIDB IMPACT Cert

Precast Concrete – Concrete Piles Certification

MS 1314 Part 1, 2, 3, 4, 5

The Malaysian Standard (MS) of precast concrete was a joint development by the Technical Committee and Working Groups of Precast Concrete Piles under the authority of Building and Civil Engineering Industry Standards Committee to promote industrial efficiency and development of precast concrete piles.

The precast concrete pile are being classified into various classes in relation to the type of piles, strength of concrete, amount of reinforcement, cement content and type of driving.

Contech offer these (5) five certification assistance of Malaysian standard of Precast Concrete MS 1314 are categorized

MS 1314 – part 1 precast concrete piles: part 1: general requirements and specifications

MS 1314 – part 2 precast concrete piles: part 2: method for determination of bending strength of precast concrete piles (bend test)

MS 1314 – part 3 precast concrete piles: part 3: precast reinforced concrete square piles (RC piles) – Class M, Class J and Class S

MS 1314 – part 4 precast concrete piles: part 4: precast pretensioned spun concrete piles (spun piles) – Class A, Class B, Class C

MS 1314 – part 5 precast concrete piles: part 5: precast prestressed concrete square piles – Class PC-X, Class PC-Y, small piles Class PCS-1 and Class PCS-2

- Comply to CIDB regulation standardized for precast concrete products

- Ensuring every construction materials achieve a high level of quality before being used in Construction industry (fit for purpose, value for money, customer satisfaction).

- Ensure construction materials guarantee the safety of the publics & construction workers

- Ensure environment preservation

- Improve the image of the country’s construction Industry

- Avoid poor quality construction materials do not enter the local market – anti dumping

Manufacturing efficiency – standardise the classes and the nominal sizes as well as specifying the minimum structural

Precast Concrete – Concrete Piles Certification Framework

What is the application process to obtain MS1314 Certificate ?

Precast Concrete

– Concrete Piles

Step 1

Engagement with approved / recognized Certification Body (CB) to obtain Product Certificate

Step 2

Step 3

Verification completed by CIDB enforcement at batching plant & issuance of CIDB PPS Certificate

Contractor Management System Certification

CQMS ISO 9001:2015 & CIS 29:2021 (Coming Soon)

CQMS sets a structured framework requirement for contractor in dealing with tenders, construction planning construction works and post-construction processes that enables continuous improvement and delivery of quality project on time.

The development of this standard was carried out by a Technical Committee established by CIDB and represented by construction industry stakeholders.

The fundamental principles of CQMS consists of these elements:

- Policies & objectives

- Documents including method statements in order to conform to the policy and achieving the objectives

- Evidence of result to prove the existence of conformance to requirements

- CQMS intention is to improve the overall quality delivery with good workmanship complying to the project specifications and other best practices

- An opportunity for contractor to implement a CIDB recognized quality management system practice in their company processes.

- Fulfilling the fundamental principle of CQMS through a practical framework

- Provide assurance that meets client requirements

- Focused on client’s needs by meeting their requirements